Popular search categories

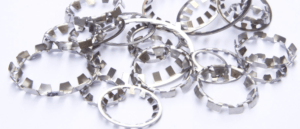

Precision metal stamping solutions since 1862.

Brandauer has built a reputation for engineering excellence, investing in the future of UK manufacturing and applying the most precise approach to developing relationships.

Brandauer is one of the largest contract presswork and stampings companies in Europe, manufacturing precision metal components for customers around the world.

We offer the complete range of services required for the supply of pressed metal components: from prototyping, design and in-house tool production (or a specialist tool transfer service) through to high-quality manufacturing and logistics.

Since Brandauer was founded more than 150 years ago, it has evolved into a world-class engineering company, specialising in the manufacture of high speed precision stamped components, in difficult materials, for a wide range of industry sectors.

Technical excellence, customer service and product value are central to everything we do.

And we pride ourselves on our ability to turn difficult or challenging requirements into positive manufacturing solutions.

New engineering consultancy service puts Brandauer on track for £2m rail opportunity

One of the UK’s leading stamping specialists is targeting over £2m of new opportunities in the rail sector after it launched a new engineering consultancy service.

Brandauer, which provides millions of precision components to customers in 22 countries every week, is looking to build on its current offering by targeting rolling stock and infrastructure specialists on projects that are aiming to take the weight out of the part.

The company’s 15-strong engineering team has been set-up to provide a full design and manufacturing service, collaborating with the client from early-stage development, giving them access to feasibility studies and prototyping to prove-out the component, to the manufacture of precision tooling and high-volume production.

This all-round consultation approach is already proving extremely popular, with a number of new opportunities secured, including a small carbon steel pierced cup that acts as an energy recovery device for use in rolling stock.

0113 2082620

0113 2082620 info@railbusinessdaily.com

info@railbusinessdaily.com 15 Mariner Court, Wakefield WF4 WF4 3FL

15 Mariner Court, Wakefield WF4 WF4 3FL