Popular search categories

About us

Reinforced Earth’s retaining wall and precast arch solutions are recognized worldwide as the preferred economical solution to ordinary and extraordinary earth retention and load support requirements for railways.

Our retaining walls, include Reinforced Earth® (MSE), T-Wall®, and TechWall™. For constructing tunnels and large culverts, Reinforced Earth offers the RECoArch® solution. All of these solutions are ideally suited to construct many types of railway structures supporting heavy freight rail, light passenger rail, and high-speed railways. With very low carbon, economical build, 120 year design life, our solutions offer significant benefits for infrastructure.

Typical rail applications include:

Retaining Walls

Reinforced Earth® retaining walls are used in many countries to support high speed and heavy railways, as well as metro and light rail transit lines. T-Wall and TechWall are complementary products.

The technology is similar to roadway applications except the design of the retaining structures is adapted to comply with rail safety requirements, especially for high-speed railways.

Railway loads differ from highway loads in regard to intensity, frequency and associated vibrations.

The 60 year experience of the Reinforced Earth companies worldwide provide significant experience regarding highly loaded structures. The inextensibility of steel strip soil reinforcements, recommended for structures supporting railways, is the guarantee of minimal deformations under high loads.

Structures beneath the tracks are designed to accommodate sudden braking decelerations, absorb the vibrations induced by passing trains inherently well as evidenced by numerous tests conducted in the USA, France and Germany.

Reinforced Earth® structures have often been used, particularly in Japan, for widening railway embankments. Since the system is versatile and built in successive layers, the Reinforced Earth® technique is well suited for the construction of new structures against, and even above existing embankments.

Bridge Abutments

Among its many earth-retaining and load-supporting applications, Reinforced Earth® has gained world wide acceptance as an economical and technically superior construction method for bridge abutments.

Reinforced Earth® bridge abutments reduce highly concentrated superstructure loads to acceptable uniform bearing pressures at the foundation level.

This eliminates the need for pile supports or other costly foundation improvements.

Reinforced Earth® railroad bridge abutments have been built in several countries since 1975.

These are designed to withstand the heavy bearing pressure and breaking stresses transmitted through the track bed. A significant feature is that, even on poor foundation soils, the profile and cross section of track over Reinforced Earth® abutments is level and regular, so long as the reinforced volume is placed in a continuous manner with the approach embankments and is carefully compacted.

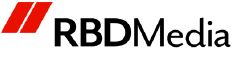

Precast Arches

Precast arches are frequently used for the construction of railway tunnels in earthen embankments or in cut and cover/eco-ducts.

The main advantages of our precast arch technique are the material and structural quality, the rapidity of installation and the adaptability to the specific requirements of each project.

Sizes can be from as little as 8m to over 30m spans.

Our method is especially efficient when building the structures over existing rail tracks under traffic when closure is not an option. Reinforced Earth® is a logical complementary technique for the construction of the spandrel walls.

Reinforcement Geosynthetics

Reinforced Earth manufacture and supply their own high strength geogrids for various basal reinforcement, load transfer platforms and challenging ground stabilisation needs.

The high strength geogrids ArmaLynk are made of co-extruded and oriented high tensile geosynthetic strips having discrete channels of closely packed high tenacity polyester (PET) yarns encased in a durable polyethylene sheath. These geosynthetic strips are welded to cross strips made from low shrinkage yarns, and together create a strong orthogonal matrix.

Reinforced Earth also offer soil reinforcement and ground stabilisation geogrids, ArmaGrid. Our ArmaGrid® line provides engineers and builders with a straightforward, full-service approach for procuring biaxial and uniaxial, polyester (PET) and polypropylene (PP) geogrids. Our geogrid performance properties are easily identifiable to specify for use on projects of all types in all construction sectors.

0113 2082620

0113 2082620 info@railbusinessdaily.com

info@railbusinessdaily.com 15 Mariner Court, Wakefield WF4 WF4 3FL

15 Mariner Court, Wakefield WF4 WF4 3FL