Popular search categories

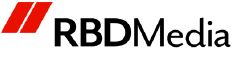

Imagine as a train operator being able to clean every train every day…

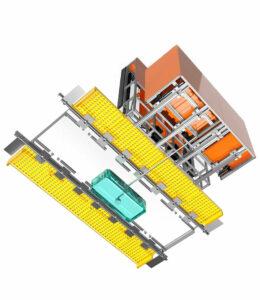

Introducing The Orange Train Wash. Rather than a massive, expensive Wash taking up swathes of space with a large amount on the civil engineering install cost, we have just a 3m x 1m footprint either side of the train where it’s needed.

With no drainage required as all the water is recycled and reused, this really is a game-changer

Fast & Efficient

Even in a depot with four Roads handling 60 trains a day, every train can be easily cleaned every day. Cleaning a carriage every 22 seconds means that even an 8 car set takes less than 4 minutes.

Imagine being able to clean every train every day and only using 1% of the usual water usage.

Chemical Free

No chemicals are required as the 85º deionised water with unique brushes cleans the carriage and the powerful air blades push the water down into the track-pan ready to be pumped back into each machine for recycling.

Very little has changed in the last 30 years in Train cleaning until now!

Say hello to intelligent cleaning

Rapid Cleaning

Cleans one train carriage every 30 seconds.

Less Water

Uses 98% less water than traditional train cleaning systems

Chemical-Free

Utilising deionised water for a safer, more hygienic clean.

Reduce – Reuse – Recycle

The Orange Train Wash recycles 90% of its resources by filtering, re-deionising and reusing the same water.

Operates in Low Temperatures

Another benefit is that when temperatures dip to 3 or lower conventional machines are unable to be utilised, but not with The Orange Train wash, the temperature is maintained at 20º before heating it back to 85º for the next approaching train

Reporting Software

Report of the carbon saving and water saving on your desktop as evidential proof of the clean.

0113 2082620

0113 2082620 info@railbusinessdaily.com

info@railbusinessdaily.com 15 Mariner Court, Wakefield WF4 WF4 3FL

15 Mariner Court, Wakefield WF4 WF4 3FL